CNC Machining vs. Sheet Metal Fabrication: A Comparative Analysis

CNC machining and sheet metal fabrication are both essential metalworking techniques, each with its own distinct characteristics and applications. Understanding these differences is crucial for selecting the most appropriate manufacturing method for specific requirements.

Definition

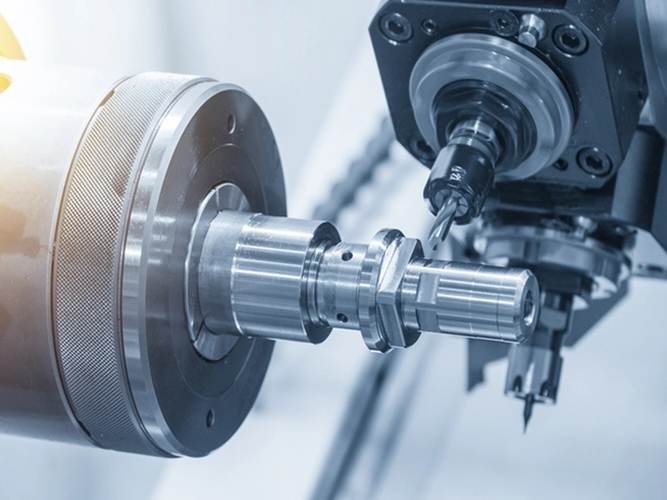

CNC Machining: CNC machining, or Computer Numerical Control machining, is a subtractive manufacturing process that utilizes computer-controlled machine tools to precisely shape workpieces according to predefined instructions. CNC machining can produce intricate and high-precision parts.

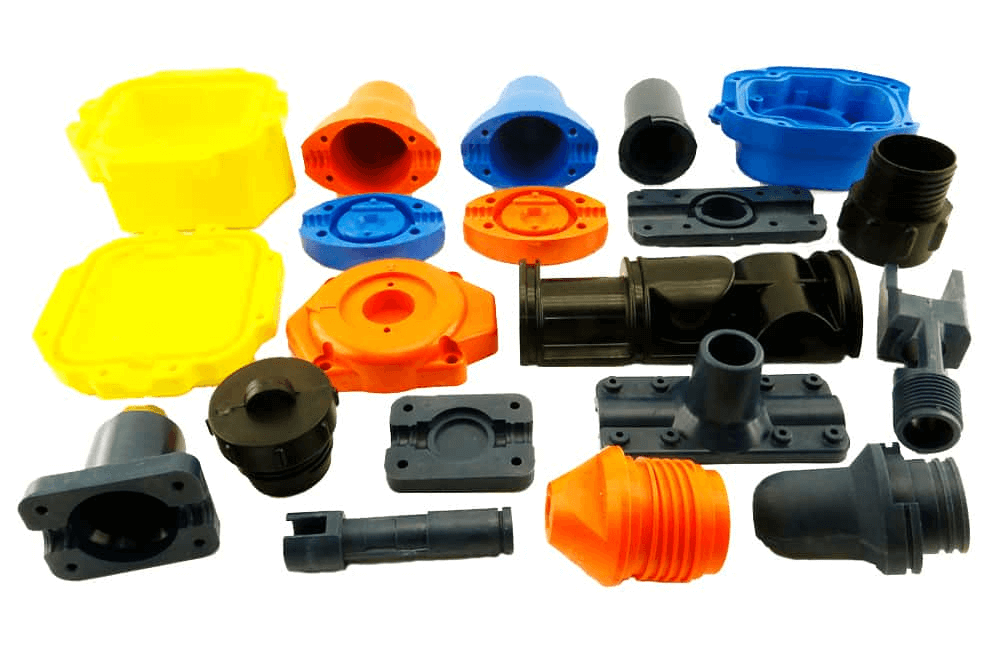

Sheet Metal Fabrication: Sheet metal fabrication is a manufacturing technique that involves transforming sheet metal into various components using processes like stamping, shearing, bending, and welding. Sheet metal fabrication is suitable for creating hollow and curved parts.

·

Manufacturing Process

·

CNC Machining: CNC machining relies on computer programming to direct the movements of CNC machine tools, which execute various machining operations, including milling, turning, drilling, and grinding, based on programmed instructions.

Sheet Metal Fabrication: Sheet metal fabrication primarily employs dies and mechanical equipment to manipulate sheet metal. Common sheet metal fabrication processes include stamping, shearing, bending, and welding.

·

Materials

·

CNC Machining: CNC machining can process a wide range of metallic materials, including steel, aluminum, copper, and titanium.

·

·

Sheet Metal Fabrication: Sheet metal fabrication commonly utilizes materials like steel sheets, aluminum sheets, stainless steel sheets, and galvanized sheets.

Applications

·

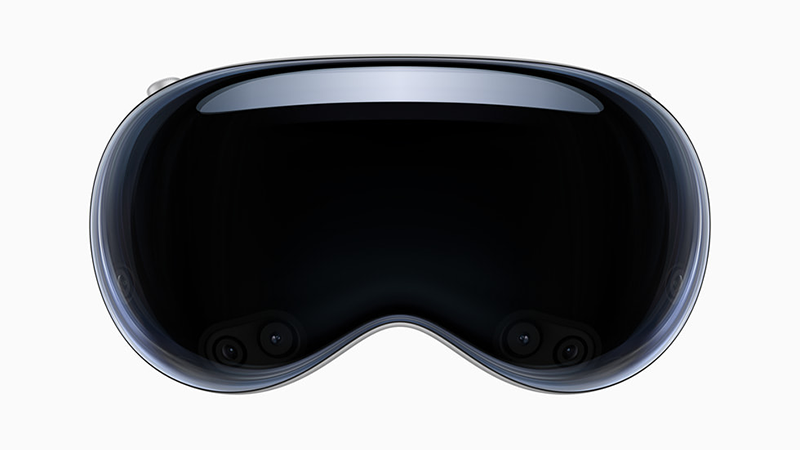

CNC Machining: CNC machining is suitable for producing complex and high-precision parts, such as aerospace components, automotive parts, and molds.

Sheet Metal Fabrication: Sheet metal fabrication is well-suited for manufacturing hollow and curved parts, including electronic enclosures, chassis, and cookware.

Advantages and Disadvantages

Feature |

CNC Machining |

Sheet Metal Fabrication |

Machining Precision |

High |

Medium |

Machining Efficiency |

Medium |

High |

Manufacturing Cost |

Higher |

Lower |

Suitable Materials |

Wide range |

Limited |

Applications |

Complex shapes, high precision parts |

Hollow, curved parts |

Conclusion

CNC machining and sheet metal fabrication are both valuable metalworking techniques, each with its own strengths and limitations. The choice between these methods depends on the specific manufacturing requirements. If intricate and high-precision parts are needed, CNC machining is preferred. For hollow and curved components, sheet metal fabrication is a suitable option.

Considerations for Choosing CNC Machining or Sheet Metal Fabrication:

·

Part Shape and Complexity: For intricate shapes and high precision, opt for CNC machining.

·

·

Material: If specific materials are required, choose the method compatible with the material.

·

·

Budget: CNC machining generally incurs higher costs; consider sheet metal fabrication for budget constraints.

·

·

Production Efficiency: For rapid production of large quantities, prioritize methods with higher efficiency.

·

This article aims to provide insights into the distinctions between CNC machining and sheet metal fabrication, enabling informed decisions regarding the most appropriate manufacturing method.