Difference between cnc and numerical control lathe

CNC lathe and CNC machining center are both CNC machine tools, but they have some differences in structure, tooling, machining range, programming and advantages and disadvantages. I will explain these aspects in detail below.

Structure difference

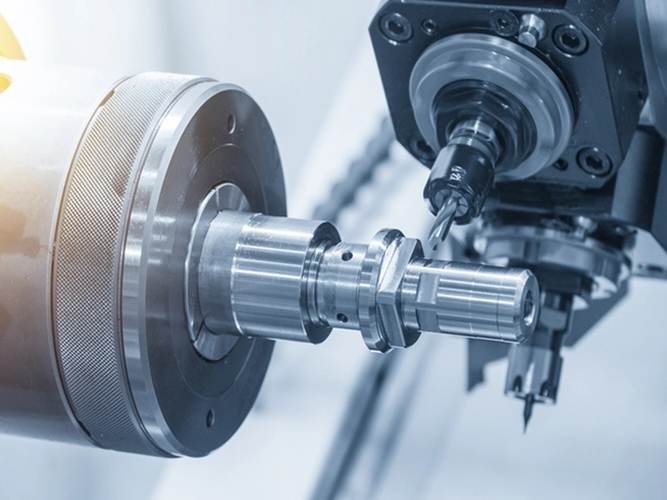

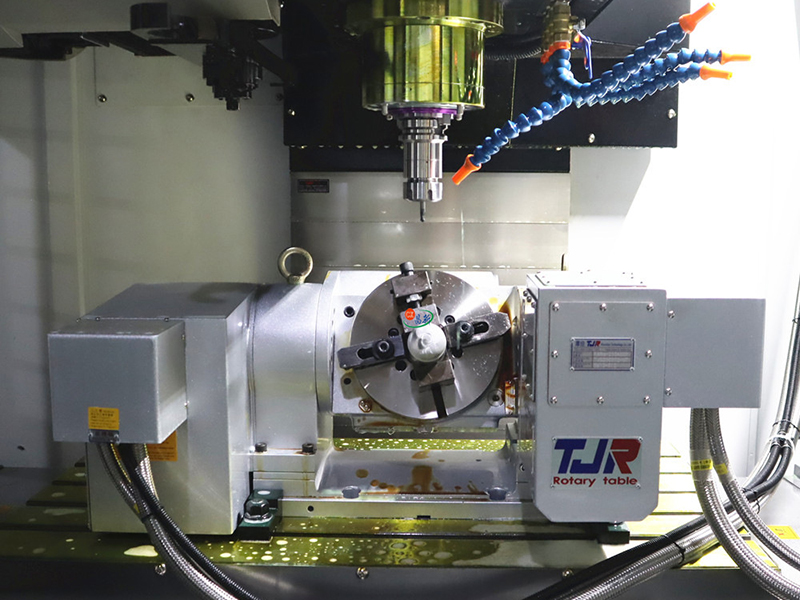

CNC machining centers are at least three-axis controlled, while CNC lathes are two-axis controlled. This means that CNC machining centers can perform more axial movements, which enables them to machine more complex parts. On the other hand, CNC lathes are mainly used for machining rotary parts .

Tooling Differences

CNC machining centers have tool magazines, while CNC lathes use tool holders.The classification of tool magazines for CNC machining centers is more than the classification of tool holders for CNC lathes, such as disc, bucket, chain, flying saucer, co-motion and so on, and most of the tool magazines have a larger tool capacity than that of tool holders for CNC lathes. This means that CNC machining centers can use more tools and thus are able to perform more machining operations.

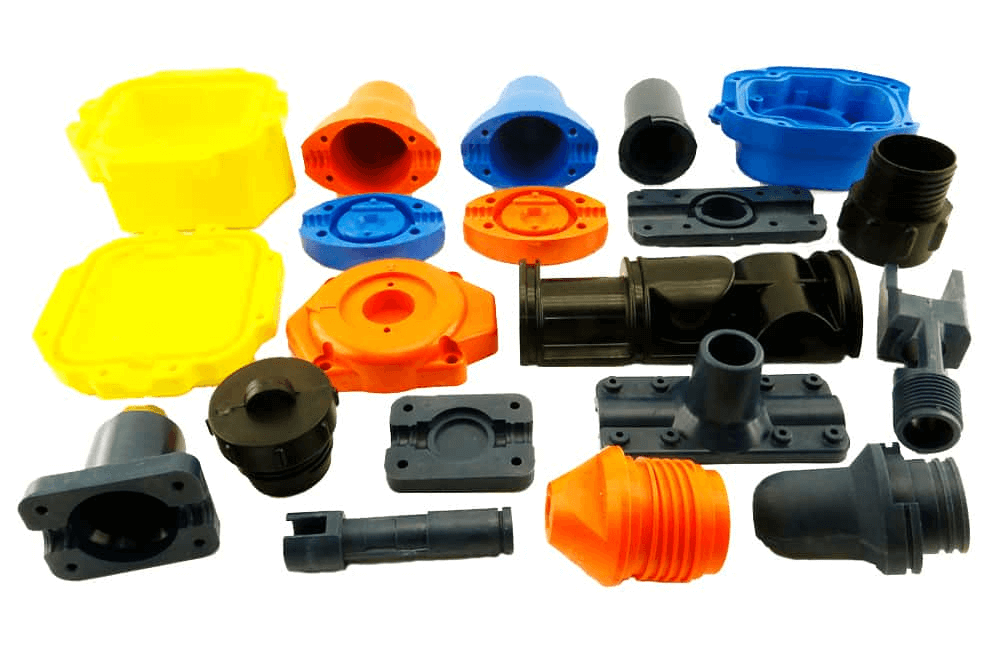

Different machining ranges

CNC machining centers have a larger machining range than CNC lathes. This means that CNC machining centers are capable of machining more complex parts, whereas CNC lathes are mainly used for machining rotary parts.

Programming Differences

Programming for CNC machining centers and CNC lathes is different in some ways. Specifically, the programming of CNC machining centers and CNC lathes is different in some aspects. This is because CNC machining centers and CNC lathes have different structures and functions, so they are programmed differently .

Advantages and Disadvantages

The advantages and disadvantages of CNC lathes and CNC machining centers also differ. For example, both CNC lathes and CNC machining centers have high machining accuracy and high machining quality. They are both capable of multi-coordinate linkage and can machine parts with complex shapes. When machined parts need to be replaced, usually only the CNC program needs to be changed and production lead time can be reduced. The machine itself has high precision and high rigidity, and can choose favorable machining dosage with high productivity (generally 3~5 times that of ordinary machine tools). High degree of automation of machine tools can reduce labor intensity. Batch production, product quality is easy to control. However, their machining routes are not easy to control, unlike ordinary machine tools as intuitive. In addition, CNC lathe requires lower quality of operators and higher technical requirements for maintenance personnel.