Six factors that affect the extrusion blow molding process?

1. Raw material: The quality of raw materials used in the extrusion blow molding process affects the quality of the final product. High-quality raw materials are essential for maintaining uniform dimensions, smooth surface finish, and consistent product quality.

2. Mold design: The design of the mold plays a crucial role in the extrusion blow molding process. The design should ensure uniform melting and injection of the raw materials, as well as proper venting to prevent air bubbles and leaks.

3. Molding temperature: The molding temperature has a significant impact on the extrusion blow molding process. The temperature should be maintained consistently to ensure uniform melting and injection of the raw materials, as well as proper bonding of the plastic parts.

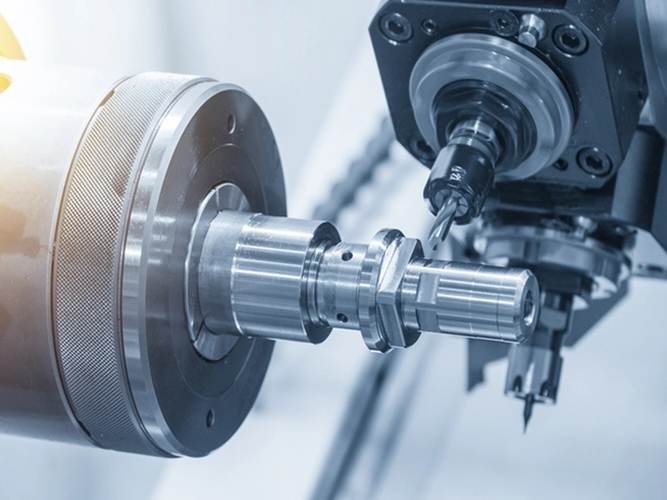

4. Extruder speed: The speed at which the extruder operates determines the flow of raw materials and the uniformity of the final product. Too slow or too fast an extruder speed can lead to defects in the final product.

5. Blowing pressure: The blowing pressure is the force applied to inflate the plastic parts. Too low a blowing pressure can result in deflated parts, while too high a blowing pressure can lead to excessive pressure on the product and reduce its lifespan.

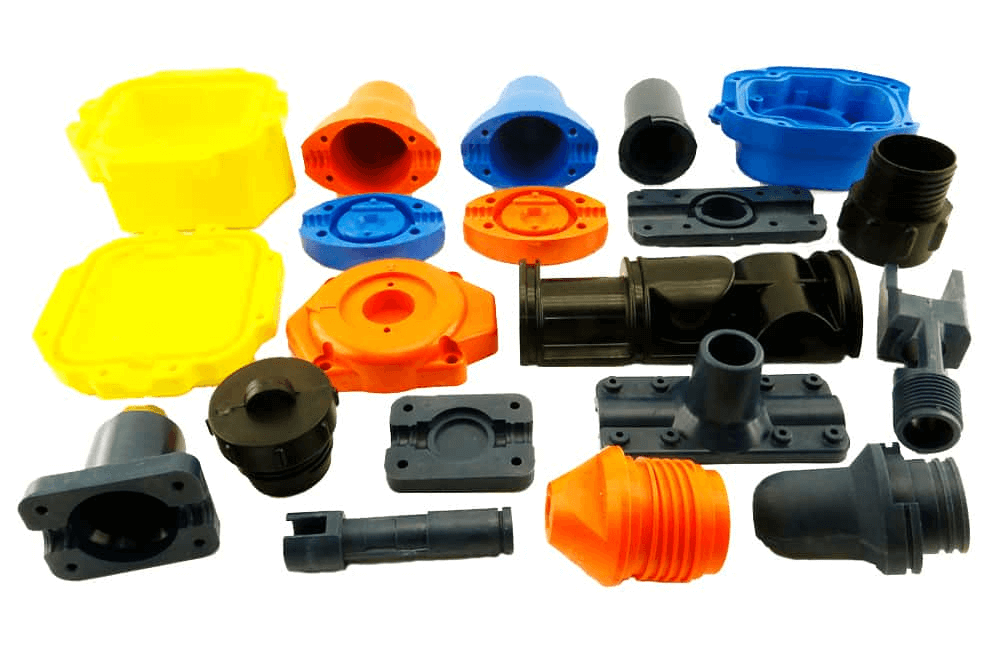

6. Part design: The design of the plastic part has a significant impact on the extrusion blow molding process. Complex and intricate parts can require additional tooling, which can result in longer production times and costlier production runs.