Understanding of extrusion blow molding process principles, benefits, and influencing factors

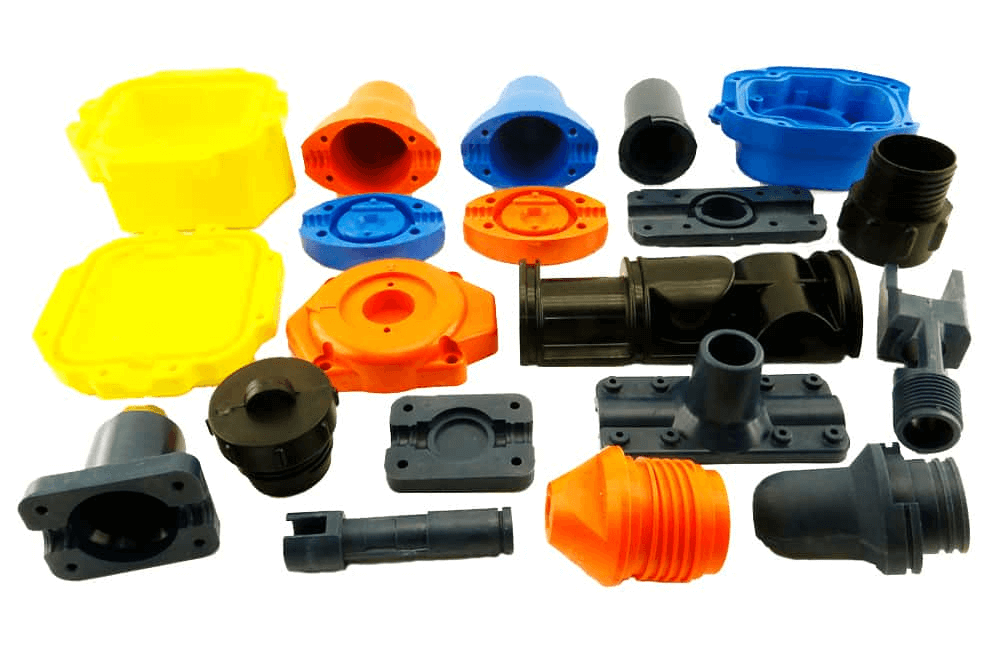

Extrusion blow molding (EBM) is a process used to produce hollow plastic bottles, containers, and other shapes using high-density polyethylene (HDPE) or polypropylene (PP). It involves heating plastic pellets or flakes into a molten state, then extruding them through a die to form a pre-shaped parison. This parison is then inflated with air or nitrogen, cooled, and ejected from the mold.

Benefits of EBM include its ability to produce complex shapes, high production rates, and good mechanical strength. It is also cost-effective compared to other molding processes. However, EBM is not suitable for all materials and may require specialized tooling and equipment.

Some influencing factors for EBM include material selection, machine design, process conditions, and mold design. Material selection is critical, as certain materials have different melting points, viscosities, and thermal properties. Machine design must ensure the proper mixing of materials, heating, and cooling to achieve the desired output. Process conditions such as injection pressure, screw speed, and cooling time can affect the quality of the final product. Mold design is important for ensuring good product quality, ease of cleaning, and long-term reliability.In summary, EBM is a versatile and cost-effective molding process that can produce complex shapes and high production rates. However, it requires careful material selection, machine design, and process conditions to ensure a high-quality final product.