Which products are suitable for rotomolding?

The rotomolding process is a common manufacturing process that creates a wide variety of plastic products by heating and pressing thermoplastics into molds and shaping them under high pressure. Unlike other processes, the rotomolding process has some unique characteristics that make it suitable for manufacturing specific types and sizes of products. In this article, we will introduce the rotomolding process and the sizes and categories of products that are suitable for use with this process.

Introduction to the Rotational Molding Process

The rotomolding process, also known as the rotational molding process, is based on the main principle of utilizing a rotating mold and the molten nature of thermoplastics, which are cooled and molded in the mold by applying high temperatures and high pressures while rotating the mold in a self-rotating and rotating motion that causes the plastic to uniformly adhere to the surface of the mold. This process not only allows for the manufacture of products with complex shapes, but also provides excellent physical properties and chemical stability. The manufacturing process of rotomolding process is relatively simple, the process cycle is short and the cost is relatively low.

Product sizes suitable for the rotomolding process

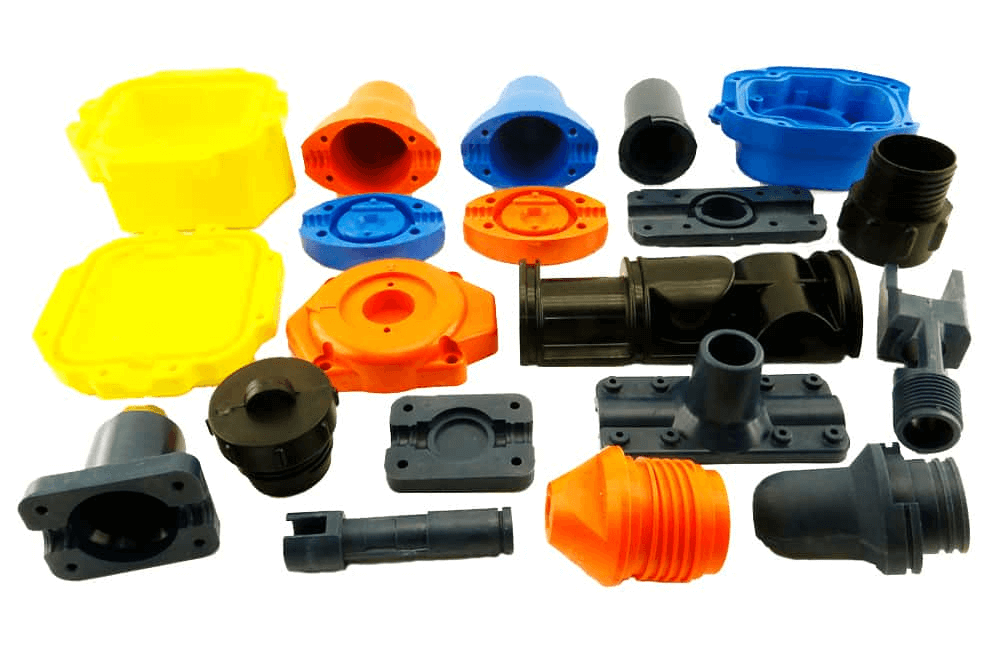

Small products The rotomolding process is suitable for manufacturing small products, such as various plastic parts, plastic connectors, plastic clips, etc.. As rotomolding process has the feature of rotating molds, small products with high dimensional accuracy requirements can be manufactured through reasonable design and adjustment of molds. The rotomolding process can also ensure the uniform molding and smooth surface of small products.

Medium-sized products The rotomolding process is also suitable for the manufacture of medium-sized products, such as plastic tanks, oil drums, water storage tanks, etc. These products usually require a certain degree of dimensional stability. These products usually require a certain degree of dimensional stability and load-bearing capacity. The rotational speed and temperature control of the mold can be adjusted to ensure that medium-sized products are stable during the molding process and have good strength and durability.

Product categories suitable for the rotomolding process

Daily necessities The rotomolding process is suitable for manufacturing a variety of daily necessities, such as plastic cups, plastic chopsticks and plastic bowls. These products usually require smooth surfaces, easy cleaning and resistance to abrasion. The rotomolding process can meet these requirements, and can also control the molding parameters to make the products have good processing performance.

Storage containers Rotomolding is also suitable for manufacturing various storage containers, such as plastic storage boxes, plastic storage bottles, plastic storage drums, etc. These containers usually need to have a certain degree of resistance to wear. These containers usually need to have a certain pressure and corrosion resistance. The rotomolding process can produce storage containers that can withstand a certain level of pressure and corrosion resistance, and at the same time ensure their surface flatness and sealing.

Conclusion

The rotomolding process is a common manufacturing process suitable for making small and medium-sized plastic products. Through reasonable design and adjustment of molds, the rotomolding process can produce products with high dimensional accuracy and excellent physical properties. The rotomolding process is suitable for manufacturing a variety of daily necessities and storage containers, which can meet the requirements of surface quality, durability and processing performance of various products. The rotomolding process is widely used in the production of plastic products because of its simple manufacturing process, short cycle time and relatively low cost.