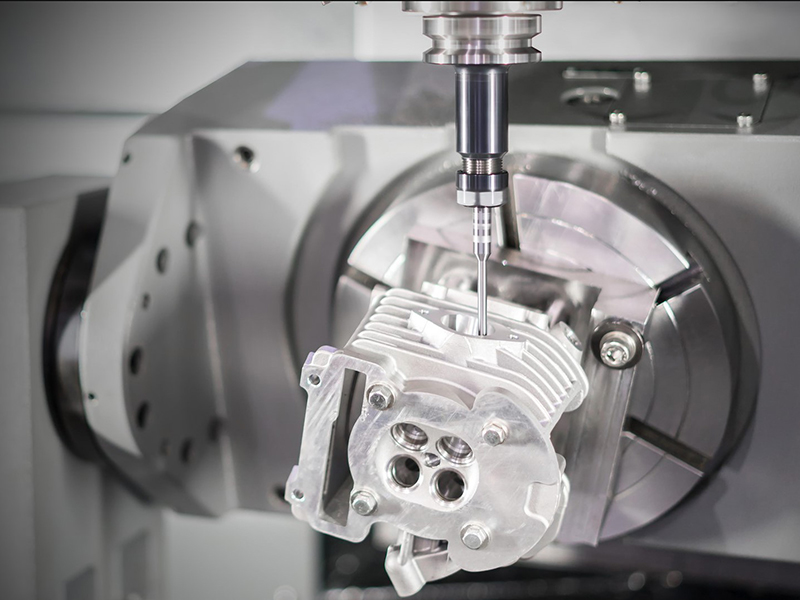

What is CNC Machining?

CNC machining Tolerance At oepin

1. Size

| Linear dimension |

+/- 0.025mm

+/- 0.001 inches

|

|---|---|

| Hole diameter (not reamed) |

+/- 0.025mm

+/- 0.001 inches

|

| Shaft diameter |

+/- 0.025mm

+/- 0.001 inches

|

| Part Dimension limit |

950*550*480mm

37.0 * 21.5 * 18.5 inches

|

2. CNC Machining Standards

| CNC Machining Standards (DIN ISO 2768-1(1991-06) | ||||||||||||||

| Tolerance class | tolerance(mm) | |||||||||||||

| Metal (ISO 2768-F) | Plastic (ISO 2768-F) | |||||||||||||

| 0.5 to 3 | Over 3 to 6 | Over 6 to 30 | Over 30 to 120 | Over 120 to 400 | Over 400 to 1000 | Over 1000 to 2000 | 0.5 to 3 | Over 3 to 6 | Over 6 to 30 | Over 30 to 120 | Over 120 to 400 | Over 400 to 1000 | Over 1000 to 2000 | |

| F | ±0.05 | ±0.05 | ±0.1 | ±0.15 | ±0.2 | ±0.3 | ±0.5 | ±0.05 | ±0.05 | ±0.1 | ±0.15 | ±0.2 | ±0.3 | ±0.5 |

2.1 General Tolerances For Shape And Position

| General tolerances for shape and position (DIN ISO 2768-2(1991-04) | |||||||||||||||

| Tolerance class | tolerance(mm) | ||||||||||||||

| Straightness and Flatness | Verticality | Symmetry | |||||||||||||

| 10 | 10 to 30 | 30 to 100 | 100 to 300 | 300 to 1000 | 1000 to 3000 | to 100 | 100 to 300 | 300 to 1000 | 1000 to 3000 | to 100 | 100 to 300 | 300 to 1000 | 1000 to 3000 | ||

| H | ±0.02 | ±0.05 | ±0.1 | ±0.2 | ±0.3 | ±0.4 | ±0.2 | ±0.3 | ±0.4 | ±0.5 | ±0.5 | ||||

| Material | Available Types & Grades |

| Aluminum |

Aluminum 2024 Aluminum 5052 Aluminum 5083 Aluminum 6063 Aluminum 6061 Aluminum 6082 Aluminum 7050 Aluminum 7075 |

| Brass/Bronze |

Brass C360 Brass 260 C932 M07 Bearing Bronze |

| Copper |

Copper C110 Copper 101 |

| Steel |

Alloy Steel 4130 Alloy Steel 4140 Mild Steel 1018 Mild Steel A36 |

| Stainless Steel |

Stainless Steel 17-4 Stainless Steel 18-8 Stainless Steel 303 Stainless Steel 304/304L Stainless Steel 316/316L Stainless Steel 416 Stainless Steel 420 |

| Titanium |

Titanium Grade 2 Titanium Grade 5 |

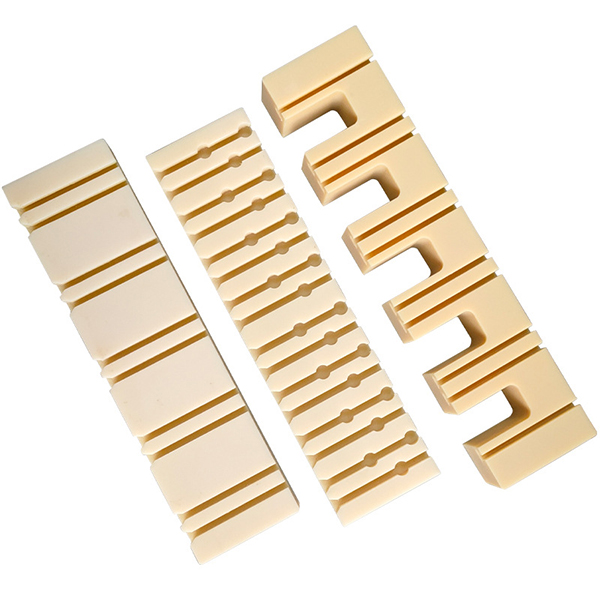

| Plastics |

ABS Nylon POM PEEK PMMA PTFE Polystyrene Polyethylene Polycarbonate |

| As machined | Description |

| As machined | Standard finish with a surface roughness of 1.6 μm (126 μin). |

| Smoothing | The standard smoothing surface roughness (Ra) is 0.8 μm (63 μin). |

| Painting | Spraying paint, pigment, or color to a solid surface as a colored protective layer. |

| Passivation | Remove ferrous contaminants or use a light coat of protective material to create a shell. |

| Powder Coating | A functional and decorative finish that is applied as a free-flowing, dry powder. |

| Anodizing | Type II (anodizing color or clear) or Type III (anodizing hard coat) |

| Polishing | Produce a smooth and shiny surface. |

| Black Oxide | Forming a black conversion coating on metal parts. |

| Bead Blasting | Removing surface deposits by applying fine glass beads at a high pressure. |

| Abrasive Blasting/Sandblasting | Smoothing and cleaning a hard surface by forcing solid particles across that surface. |

| Electroplating/Plating | Form a thin coherent metal coating on an electrode. |

| Brushing | Polishing the metal with grit resulting in a unidirectional satin finish. |

| Chromate Conversion Coating | Increase the corrosion resistance while maintaining conductive properties. |

If you need unconventional materials and custom surface treatment, please contact us.

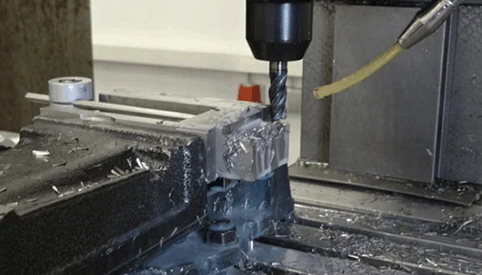

1. Is My Part a Good Fit for CNC Turning?

2. How to Reduce the Cost of Machining Parts?

- The best way to reduce machining time is to design features that can be processed quickly, such as by selecting the correct inner corner radius, reducing the cavity depth, increasing the wall thickness, limiting the thread length, and designing holes of standard size.

- The material cost can be reduced by considering the size of the required blank and the cost and machinability of bulk materials (softer alloys process faster).

3. What Parts Can Be Made with CNC Turning?

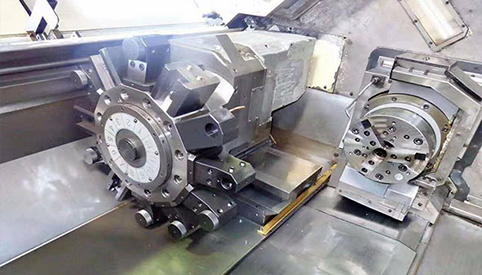

4. What is CNC Turning Center - Difference Between CNC Lathes and CNC Turning Centers

5. Heat Treatment of Precision Turned parts

6. How to start my CNC machining project?

Enjoy our fast & free delivery

medical industry

Automotive industry

Marine industry

Agricultural industry

Machine tool industry

Military industry

High-tech industry

Food industry

Aerospace industry

Semiconductor industry